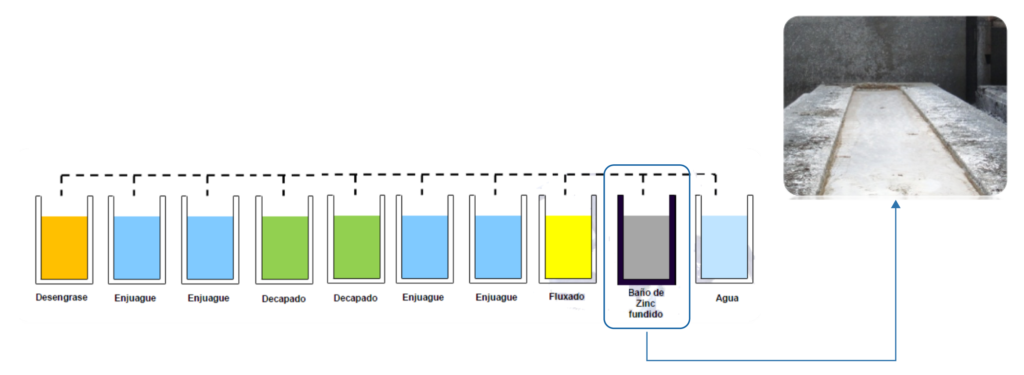

HOT IMMERSION GALVANIZING

Here at PROMESA we have hot immersion galvanizing services, where we can galvanize pieces from up to 12m by double immersion. We work by the international standards of ASTM-A123 and ASTM-153 and according to the valid mexican norm of galvanizing NMX-H-0004.

We dispose of a trustworthy supplier certificate issued from LAPEM

The hot immersion galvanizing is a process by which corrosion that attacks materials made from steel or iron is avoided, it is the top anti-corrosive protection for industrial work, civilian, commercial and urban structures.